Montana Aerospace: Fast Charging as a crucial factor

Montana Aerospace Division ASTA sets new standards for high-voltage components for E-Mobility

Reinach (pta010/03.06.2025/08:00 UTC+2)

Montana Aerospace division ASTA - Energy Segment - sends a clear signal: With its production site in Baoying, ASTA has been positioning itself as an innovation driver for the mobility transition in the world's largest and dynamically growing automotive market, China, since 2005 with its global multi-technology strategy in the field of copper winding wire for electric motor stators. Since then, ASTA has been supplying efficient and reliable copper solutions for China's automotive market and energy infrastructure. At the same time, ASTA strengthens its manufacturing expertise at the Austrian site to develop innovative products for e-mobility in the future.

"As a leading manufacturer of insulated copper wires, ASTA has been playing a key role in the energy transition for decades", says Montana Aerospace Co-CEO Michael Pistauer. "The strategic development and the associated targeted investments are consistently geared towards future trends and ASTA has more than 200 years of combined manufacturing expertise–the best foundation for developing innovative technologies and successfully driving the Group's long-term growth and opening up new markets."

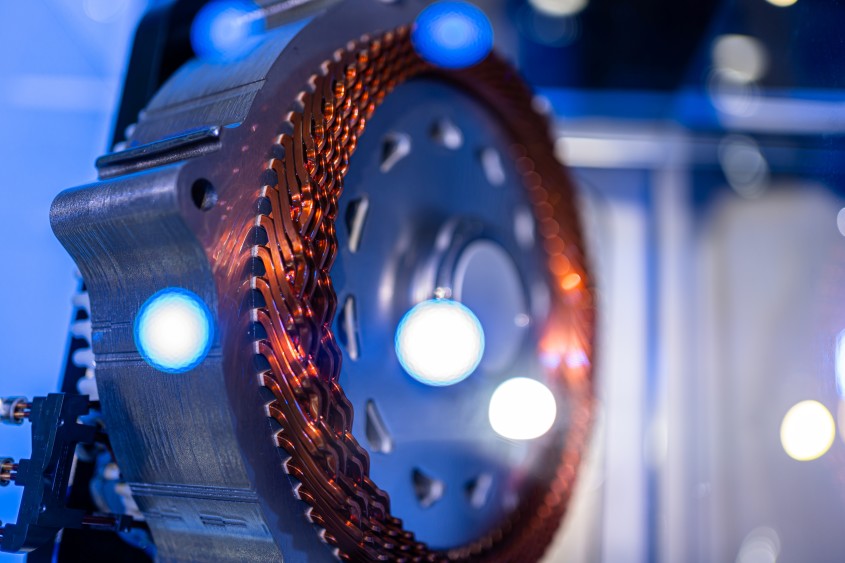

Charging times are the key to everyday usability and broad acceptance of e-mobility. Particularly in the 800V+ high-voltage segment, which reduces charging times by up to 50% for end customers, the focus is increasingly shifting to the insulating wire as a central component of the electric drive. The two next-generation insulation systems are related to this: while PEEK (polyether ether ketone) scores with its mechanical resistance, PI (polyimide) offers an attractive price-performance ratio–crucial for mass distribution. Due to its technological leadership and strategic cooperation with machine specialist Rosendahl-Nextrom in the field of PEEK extrusion as well as decades of experience with coating systems in the PI area, ASTA is already prepared to process both insulation systems in the future.

"Our presence in China enables us not only to follow developments in e-mobility close to the market, but also to actively shape them–especially in the dynamic 800V+ segment, which will define the charging times of the future," explains Karl Schäcke, CEO of ASTA. "With our technological leadership and close cooperation with Austrian mechanical engineering partners, we are playing a key role in shaping the next generation of electric drive systems."

Technological expertise meets Austrian mechanical engineering expertise

Development activities relating to PEEK extrusion and PI coating benefit from strong partnerships with renowned mechanical engineering companies from Austria. The machinery at the ASTA headquarters in Oed was recently expanded to include a state-of-the-art extrusion line from Rosendahl Nextrom in Pischelsdorf am Kulm and a coating machine from K industries–MAG machines in Deutschlandsberg.

These investments enable the customized production of robust high-performance components for electric motors, particularly in the premium automotive segment, as well as in rail and bus transport. The insulating wires are characterized by their small cross-sections, high thermal load capacity and energy-efficient processing.

Research, development and global presence as success factors

ASTA continuously invests in the close integration of production, engineering and R&D. New insulation materials and manufacturing processes are developed in cooperation with technical universities to further increase material and energy efficiency. With production sites in Bosnia, Brazil, China, India and the development center in Oed, ASTA operates close to the markets and reacts flexibly to customer needs.

Think Green – Amplify E-Power

ASTA is driving forward the vision of a sustainable future at full speed with precise, efficient and durable copper components for the electric drive of tomorrow.

About Montana Aerospace AG

Montana Aerospace AG is a leading manufacturer of system components and complex assemblies for the aerospace industry, with worldwide engineering and manufacturing operations. The Company has approximately 7,600 highly skilled employees at 22 locations on four continents – designing, developing and producing ground-breaking technologies for tomorrow's aerospace and energy industries made of aluminum, titanium, composite, copper and steel.

About ASTA Group

The ASTA Group, headquartered in Oed, Austria, has evolved into a globally operating company since its establishment in 1814. With six locations in Austria, Bosnia, Brazil (2x), India, and China, ASTA employs approximately 1,400 employees. The company is a Hidden Champion in manufacturing tailor-made copper components for high-performance applications in power transformers, power generation units and e-mobility. In the fiscal year 2024, the ASTA Group generated revenues of approximately EUR 643 million. With 210 years of experience and expertise in the production and advancement of precisely insulated flat wires, ASTA is a trusted partner to leading energy technology manufacturers worldwide, such as Siemens Energy, Hitachi Energy, Andritz, or GE Vernova.

Sustainability is deeply embedded in ASTA's corporate strategy. The group takes a pioneering role in the industry with its in-house copper recycling capabilities. Since 2022, the company, in collaboration with partners, has been developing a circular copper platform and actively shapes the global energy transition in a resource-efficient, energy-optimized, and ecologically sustainable manner, striving for the best possible ecological footprint.

(end)

| Emitter: |

Montana Aerospace Alzbachstrasse 27 5734 Reinach Switzerland |

|

|---|---|---|

| Contact Person: | Jürgen Beilein | |

| Phone: | +43 664 831 28 41 | |

| E-Mail: | communication@montana-aerospace.com | |

| ISIN(s): | CH1110425654 (Share) | |

| Stock Exchange(s): | SIX Swiss Exchange |