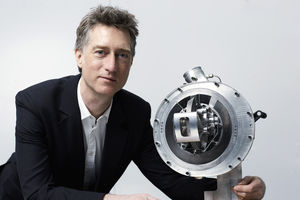

UK inventor Steve Lindsey named European Inventor Award 2017 finalist

Munich (pts022/26.04.2017/11:30) * British inventor Steve Lindsey nominated for EPO prize for developing energy-efficient, oil-free rotary air compressor

* Lindsey's Blade Compressor can deliver energy savings of more than 20%

* Air compressors, found in many industries, make up 10% of Europe's industrial electricity use

* EPO President Battistelli: "Lindsey's invention has the potential to make an impact on worldwide energy consumption."

Air compressors are everywhere, even if we don't take much notice of them. These mechanical devices are used in countless applications, from manufacturing machinery to fridges and air conditioning. And they use up vast amounts of energy - some 10% of Europe's overall industrial electricity use. Despite their prevalence, modern piston compressors have remained largely unchanged since the 1930s, and their antiquated design makes them inefficient. No one had managed to come up with an effective solution to this problem - until now. With his Blade Compressor, British inventor Steve Lindsey has devised a more efficient, oil-free rotary compressor that offers a greener solution to traditional compression technology, and can deliver energy savings of more than 20%.

For this achievement, Steve Lindsey has been nominated as one of three finalists for the European Inventor Award 2017 in the category "Small and Medium-Sized Enterprises". The winners of the 12th edition of the EPO's annual innovation prize will be announced at a ceremony in Venice on 15 June.

"Steve Lindsey's invention offers a clever, highly-efficient alternative to traditional air compressors, and is poised to shake up the compression industry," said EPO President Benoît Battistelli announcing the European Inventor Award 2017 finalists. "Because air compressors are used across such a large number of industries, it also has the potential to make an impact on worldwide energy consumption and cut carbon footprints across many energy-intensive sectors."

A new take on an old problem

A natural technical problem-solver from a young age, as well as a motorsport enthusiast, Lindsey has raced professionally and worked as a test-driver for a German car company for many years. His fascination with making continuous improvements to technology made him well-placed to take on the challenge of improving such a widely used, but often overlooked technology as compressors.

Lindsey says: "To begin with I didn't know a great deal about compressors, like many people. And then I read that 10 percent of electricity that is used within Europe across all industries goes into compressors. It's a fantastically high figure. And I realized that if you could make a difference to that, you could potentially make a big difference to energy usage across Europe."

Modern air compression dates back to the development of the piston compressor in the early 20th century. Similar to a petrol engine, these compressors use a piston to draw air into a cylinder on the outward stroke and compress this air after the piston has reversed its motion and moves inward. Valves control incoming and exiting air. However, there are several flaws in this design: a piston air compressor is noisy, valves and seals are never airtight and, crucially, it only compresses air on the piston's down stroke. Half of a piston compressor's movement is essentially wasted energy.

Lindsey's Blade Compressor improves on each of these design weaknesses. It features a rotating piston blade inside a circular chamber that simultaneously compresses air and induces new air into the chamber in one continuous movement. As the blade moves within the chamber, it induces air behind it and compresses air in front. The compressed air is released just before the piston blade slides through a slit in a spinning disc, which bisects the chamber: the air that was behind the piston is now in front of it and is compressed while more air is drawn in from what is now behind the blade.

Unlike a traditional piston compressor, which must stop and change direction, Lindsey's device features a blade rotating endlessly in one direction, never stopping and starting. This makes it considerably smoother, quieter and more reliable. It is also the first new compression technology which is inherently oil-free, and as such it leaks less.

Significant energy-saver

To market his invention, Lindsey founded the company Lontra in 2004. The firm initially targeted the wastewater sector, an energy-intensive area that accounts for roughly 1% of the UK's total energy budget, similar to that of other European countries.

In 2012, Lontra conducted its first major trial of the Blade Compressor at a British waste water treatment facility. The blade compressor demonstrated a 20% reduction in electricity consumption - a major shakeup in an industry used to much smaller, incremental gains. "A true step change in energy usage from a relatively simple change," Lindsey says.

According to Lontra, with the breadth of its potential uses, the Blade Compressor could save 2 terawatt hours of electricity in Europe a year (roughly the electricity consumption of a city of 200 000 households) and 860 000 tonnes of CO2 (roughly the same annual output of

180 000 passenger vehicles).

Global potential

The global market for air compressors is estimated to be EUR 23.5 billion (GBP 20 billion) a year. To best meet customer demands across a variety of industries in which air compressors are used, Lontra is run as an intellectual property firm, licencing Blade Compressor technology for other manufacturers, rather than operating as a manufacturer itself. In 2014, the small company, which employs approximately 20 people, agreed a deal with Swiss multinational pump manufacturer Sulzer reportedly worth EUR 717 million (GBP 600 million) to supply Blade Compressors to wastewater treatment plants.

Lindsey also has his sights set on bringing his compressor to other industries. In 2016, Lontra won funding from the EU's Horizon 2020 programme for research and innovation. This will help it to introduce the Blade Compressor technology into the pharmaceutical and food sectors, where it will be used for pneumatic conveyors - a way of moving products and bulk materials during the manufacturing process by blowing them through tubes.

Passion for problem-solving

After studying Chemistry at the University of Bristol, Steve Lindsey worked at a consultancy firm as a technical project manager. When his attention was drawn to the field of air compressors, he began to experiment, developed a working concept and submitted a patent for the Blade Compressor in 2003. Lontra was established to bring his invention to market.

Lindsey is a passionate supporter of entrepreneurism and small and medium enterprises. In 2015, he won the UK's Manufacturing Entrepreneur of the Year award. His Blade Compressor was named the "most innovative new technology of the year" at the Water Industry Achievement Awards (2013) and the "Top Energy Product/Service" at the Environment and Energy Awards (2015).

And he shows no sign of stopping: "I think the exciting thing about compressors is they are behind nearly every part of modern life - from the compressors that open the doors on a train or a bus to the compressors that power the tools in factories or power the spray guns in factories to compressors in air conditioning or in the back of your fridge. And our compressor can potentially replace all of them over time."

Additional resources

Video and photo material - http://www.epo.org/news-issues/press/european-inventor-award/2017/lindsey.html

Read more about the inventor - http://www.epo.org/learning-events/european-inventor/finalists/2017/lindsey.html

View the patent: EP0933500 - https://worldwide.espacenet.com/publicationDetails/biblio?CC=EP&NR=0933500B1&KC=B1&FT=D&ND=4&date=20030827&DB=EPODOC&locale=en_EP

The next James Dyson?

With his innovative, energy-saving approach to air compressor design, Steve Lindsey is breathing new life into British manufacturing. Like European Inventor Award finalist James Dyson http://www.epo.org/learning-events/european-inventor/finalists/2006/dyson.html (Lifetime, 2006), who re-envisioned the vacuum and turned it high-tech by adding cyclonic separation, Lindsey is breathing new life into the huge but relatively stagnant compressor sector.

About the European Inventor Award - http://www.epo.org/learning-events/european-inventor.html

About the European Patent Office (EPO) - http://www.epo.org/news-issues/press/background/epo.html

Contacts:

Jana Mittermaier

Director External Communications/EPO Spokesperson

European Patent Office

press@epo.org

Rainer Osterwalder

Director Media Relations / Press Spokesperson

European Patent Office

Tel. +49 (0)89 2399 1820

Mobile: +49 (0)163 8399527

rosterwalder@epo.org

Jonathan Weinberg

Shepard Fox Communications

Tel. +44 2033 184491

Mobile: +44 7947 141014

jonathan.weinberg@shepard-fox.com

| Aussender: | Shepard Fox Communications |

| Ansprechpartner: | Jonathan Weinberg |

| Tel.: | +44 2033 184491 |

| E-Mail: | jonathan.weinberg@shepard-fox.com |

| Website: | www.shepard-fox.com |