Embedded World 2017 highlight: GE presents new Industrial Internet Control System

Global launch of new modular Industrial PCs

Nuremberg (pts026/14.03.2017/12:30) * Industrial Internet Control System from GE greatly improves operational equipment efficiency and enables quantum leaps in productivity

* Unique solution combining connected machine controllers with cloud connectivity, advanced analytics software and apps for plant and asset control in real time

* Global launch of new modular Industrial PCs, marking new era of customized computing platforms

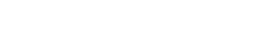

* Next generation COM Express modules with unique cooling technology

At Embedded World 2017 in Nuremberg, Germany (March 14-16), GE's Automation & Controls (Hall 3, Booth 543) presents for the first time in Europe its new Industrial Internet Control System IICS, a central control system for industrial asset and plant control on the basis of analyzed machine data. GE also launches the first two models of a new line of Industrial PCs (IPCs), introducing a new concept of modular design, and allowing a higher level of customization. The new solutions presented at the tradeshow also include the next generation of COM Express modules, specifically designed for demanding conditions.

The Industrial Internet Control System IICS: Traditional control systems are often inadequate for realizing the full potential of the Industrial Internet because they are self-contained and operate on a simple closed loop, whereas IICS connects distributed controls and pools local streams of data for simultaneous processing and analysis.

The data analytics are not only happening in the cloud, but also on the edge in the plant and at the machine. With IICS, GE enables companies to use data better and faster for smarter operating decisions, leading to enhanced process performance and increased productivity.

"IICS is the pathway to the next stage of the Industrial Internet. We are going beyond Big Data, as it is not about data volume anymore, but using data more effectively. Not all data needs to be sent to the cloud, efficient data processing already starts at the machine level", says Rudolf Krumenacker, Head of Engineering and Site Leader at GE in Augsburg, Germany.

IICS consists of a flexible combination of connected controllers, I/O modules, secure cloud connectivity, advanced analytics software and apps, used to collect and analyze data to then send back specific decisions as commands to the individual machine controllers.

Besides IICS, GE presents a new series of Industrial PCs (IPCs) at Embedded World. They mark the end of the era of maximizing the degree of standardization in IPCs and introduce a new concept of modular design, allowing a new level of customizing IPCs to specific client needs.

One of the new Industrial PCs is the RXi2-EP. Optimized for heavy usage in harsh industrial environments, it delivers mid-to-high performance computing capabilities to run e.g. data analytics applications right at the machine, enabling improved control of operations in real time.

"Our new, customized IPCs deliver on the promise of lower total cost of ownership. When compared to standardized products, they require less maintenance and have longer life-cycles. They allow for operating periods of 7 to 10 years throughout which the computers can continuously be deployed, hardly requiring reconfiguration. Expenses for software modifications are lower, and there is less regression testing", says Rudolf Krumenacker.

All aspects of the new IPCs have been designed to further advance the Industrial Internet, as they provide more computing power at the heart of GE's Field Agents which are the critical link and gateway of machine controllers to data analytics in the cloud. Furthermore they are preconfigured for secure data transmission via secure networks.

The new RXi2-EP IPC is the perfect platform for running industrial apps right at the machine, even in the harshest environments. The core of the RXi2-EP IPC architecture is GE's COM Express modular CPU platform. It allows users to flexibly combine the IPC's carrier with a range of COM Express modules for maximum customization to specific application needs. GE's COM Express platform architecture separates the processor module and carrier card, allowing the life of the subsystem to be extended by offering a simple, cost-effective upgrade of the processor alone.

One of the new COM Express modules presented at Embedded World is the bCOM6-L1800, based on the capabilities of Intel® core processors. It has been designed specifically for industrial control applications in rugged environments which require the highest reliability and protection against shock, vibration, moisture, dust, chemicals as well as heat. Thanks to a unique cooling technology, the processors deliver full performance with no throttling over the entire temperature range of -20°C to +80°C.

All new products will be presented at GE's Automation & Controls Press Briefing on Tuesday, March 14, 2017, at 3.30pm at the GE booth 543 in Hall 3. Our experts will be glad to discuss the latest trends and products with you in person.

GE's Automation & Controls combines what was formerly known as GE's Intelligent Platforms and Alstom's Power Automation & Controls. This alliance makes GE a leading provider of automation and controls solutions globally. The automation and controls technology solutions are designed specifically to harness the power of the Industrial Internet. They provide the foundation to connect machines, enable the collection of data from assets and processes, and help customers leverage that data to derive actionable insights.

About GE's Automation & Controls solutions

GE is a leading provider of automation and controls technology and services for power generation, distribution and adjacent applications across industry. Our differentiated Industrial Internet solutions enable customers to optimize equipment performance and ensure reliable and efficient operations by connecting their machines, data, insights and people. Our dedicated team includes some of the best minds in automation capable of solving our customers' toughest challenges.

For more information, please contact:

Nicole Jung

Shepard Fox Communications

nicole.jung@shepard-fox.com

Tel. +43 7202 30798

Mobile +353 86 8854119

Maria Diviney

Shepard Fox Communications

maria.diviney@shepard-fox.com

Tel. +44 2033 184491

Mobile +44 7444 314547

| Aussender: | Shepard Fox Communications |

| Ansprechpartner: | Maria Diviney |

| Tel.: | +44 2033 184491 |

| E-Mail: | maria.diviney@shepard-fox.com |

| Website: | www.shepard-fox.com |